Introduction: The Invisible Engine of Fit and Comfort

In the intricate world of textiles and apparel manufacturing, few components are as crucial yet understated as Rubber Band Thread. This specialized elastic yarn is the fundamental element that provides stretch, recovery, and shape retention to a vast array of fabrics and finished products. Unlike a standard sewing thread, rubber band thread is engineered with a core of elastic material—traditionally natural rubber latex or modern synthetic elastomers—that allows it to stretch significantly and then return to its original length. This unique property is the invisible engine behind the comfort and functionality of modern clothing. It is what allows waistbands to hug without constricting, cuffs to seal around wrists and ankles, and sportswear to move seamlessly with the body. The application of Rubber Band Thread extends far beyond simple garment construction; it is integral to the production of socks and hosiery, medical compression garments, upholstery, and even in crafting for decorative shirring and smocking. Understanding this material's composition, types, and specifications is essential for designers, manufacturers, and serious crafters who aim to create durable, comfortable, and high-performing textile products that meet contemporary demands for both aesthetics and functionality.

- Core Function: Provides controlled stretch and recovery (elasticity) to fabrics and seams.

- Ubiquitous Application: Found in apparel, accessories, medical textiles, and home furnishings.

- Performance Critical: Directly impacts garment fit, comfort, durability, and shape over time.

- Design Enabler: Allows for innovative fits and styles that rigid fabrics cannot achieve.

Material Science: What is Rubber Band Thread Made Of?

The performance and feel of Rubber Band Thread are intrinsically linked to its core material. Historically, the gold standard has been natural rubber latex, prized for its excellent elongation, smooth recovery, and soft hand-feel. However, natural rubber has limitations, including potential allergenicity and degradation from oils, chlorine, and UV exposure. This has driven the development and adoption of advanced synthetic elastomers. The demand for latex free rubber band thread has grown significantly, leading to the use of materials like Thermoplastic Polyurethane (TPU) and silicone. TPU-based elastic threads offer superior resistance to chlorine (essential for swimwear), sweat, oils, and ultraviolet light, while also providing consistent performance and often greater durability. The choice between natural and synthetic cores is a fundamental design decision. Natural rubber may be preferred for its exceptional softness and stretch in certain applications, while synthetic options are chosen for their chemical resistance, longevity, and hypoallergenic properties. Often, the elastic core is covered by wrapping it with staple fibers like cotton, polyester, or nylon. This covering protects the elastic core from abrasion during sewing and wear, provides a better surface for dyeing, and improves the thread's handling and grip in sewing machines.

| Core Material | Key Advantages | Ideal Applications |

| Natural Rubber Latex | Excellent elongation, smooth recovery, soft hand-feel. | General apparel, intimate wear, products where supreme softness is key. |

| Synthetic Elastomers (e.g., TPU) | Chlorine/UV/oil resistant, durable, hypoallergenic, consistent. | Swimwear, activewear, medical textiles, latex free requirements. |

Key Properties and Performance Specifications

Selecting the correct Rubber Band Thread requires an understanding of key technical properties that define its performance in the final product. Foremost among these is tensile strength and elastic recovery. High strength rubber band thread is engineered to withstand significant and repeated stretching without breaking or permanently deforming. This is measured by its breaking strength (in grams-force or centiNewtons) and its percentage of elastic recovery after a defined stretch. Such threads are non-negotiable for high-stress applications like sportswear, heavyweight denim waistbands, or industrial textiles. Equally important for many applications is aesthetics. Clear elastic rubber band thread is a transparent or translucent variant, often made from pure synthetic elastomer. Its primary role is to provide structural elasticity without being visible on the finished garment, making it perfect for applications like stabilizing shoulder seams, creating invisible casings in sheer fabrics, or anywhere the thread must not affect the fabric's color or print. Other critical specifications include denier (thickness), heat resistance (for high-temperature dyeing and pressing), and color fastness to washing, light, and perspiration.

- Tensile Strength & Break Elongation: Defines how much force it can take and how far it can stretch before breaking.

- Elastic Recovery (%): The percentage of stretch it can recover from; high recovery prevents "bagging out."

- Thickness (Denier): Affects the visibility and bulk of the seam; finer deniers for lightweight fabrics.

- Chemical Resistance: Especially to chlorine, salt, sweat, and oils for performance and swimwear.

Primary Applications in the Textile Industry

The versatility of Rubber Band Thread is demonstrated by its wide range of critical applications. In apparel, it is the backbone of comfortable, functional clothing. As a fundamental rubber band thread for garments, it is integrated into waistbands, cuff and ankle bindings, bra straps, and necklines to provide lasting elasticity and shape. In swimwear and activewear, its chlorine and sweat resistance is vital. For sewists and manufacturers, elastic rubber band thread for sewing opens creative and functional techniques. When wound onto a sewing machine bobbin and used with a standard thread on top, it creates beautiful shirring or smocking effects. It is also used in coverstitch and overlock machines to create stretchy seams in knit garments. Beyond clothing, this thread is essential in the production of socks and hosiery to provide the top-band elasticity. It finds use in medical textiles for compression garments, in furniture upholstery for fitted covers, and in accessories like hats and masks. Its role is always the same: to introduce durable, reliable stretch where it is needed.

| Application Sector | Specific Use | Key Thread Requirement |

| Apparel & Fashion | Waistbands, cuffs, bra straps, swimwear, leggings. | High recovery, durability, color fastness, chlorine resistance for swim. |

| Sewing & Crafting | Shirring, smocking, elasticated seams in home-sewn garments. | Easy handling, compatibility with home sewing machines. |

| Hosiery & Socks | Top bands (welts) to keep socks up. | Fine denier, consistent elasticity, softness against skin. |

| Technical Textiles | Medical compression, sportswear, upholstery. | High strength, specific chemical resistance, medical-grade compliance. |

Selecting the Right Rubber Band Thread: A Buyer's Guide

Choosing the optimal Rubber Band Thread is a technical decision that impacts product quality. Start by defining the end-use environment. Will the final product be exposed to chlorine, frequent high-heat washing, or UV light? This points toward synthetic elastomers. Is skin contact and allergen sensitivity a concern? This necessitates latex free rubber band thread. Next, consider the mechanical demands: a heavyweight fabric or a high-compression garment requires a high strength rubber band thread with excellent recovery to prevent premature fatigue. For sheer or lightweight fabrics where the thread should not show, a fine denier clear elastic rubber band thread is essential. The construction of the thread itself matters; a braided or covered elastic thread typically offers better seam abrasion resistance and sewing performance than a bare elastic monofilament. Finally, work with a supplier that can provide technical data sheets specifying core composition, breaking strength, elongation, and shrinkage rates to make an informed, scientific selection rather than a guess.

Why Source from a Specialized Manufacturer?

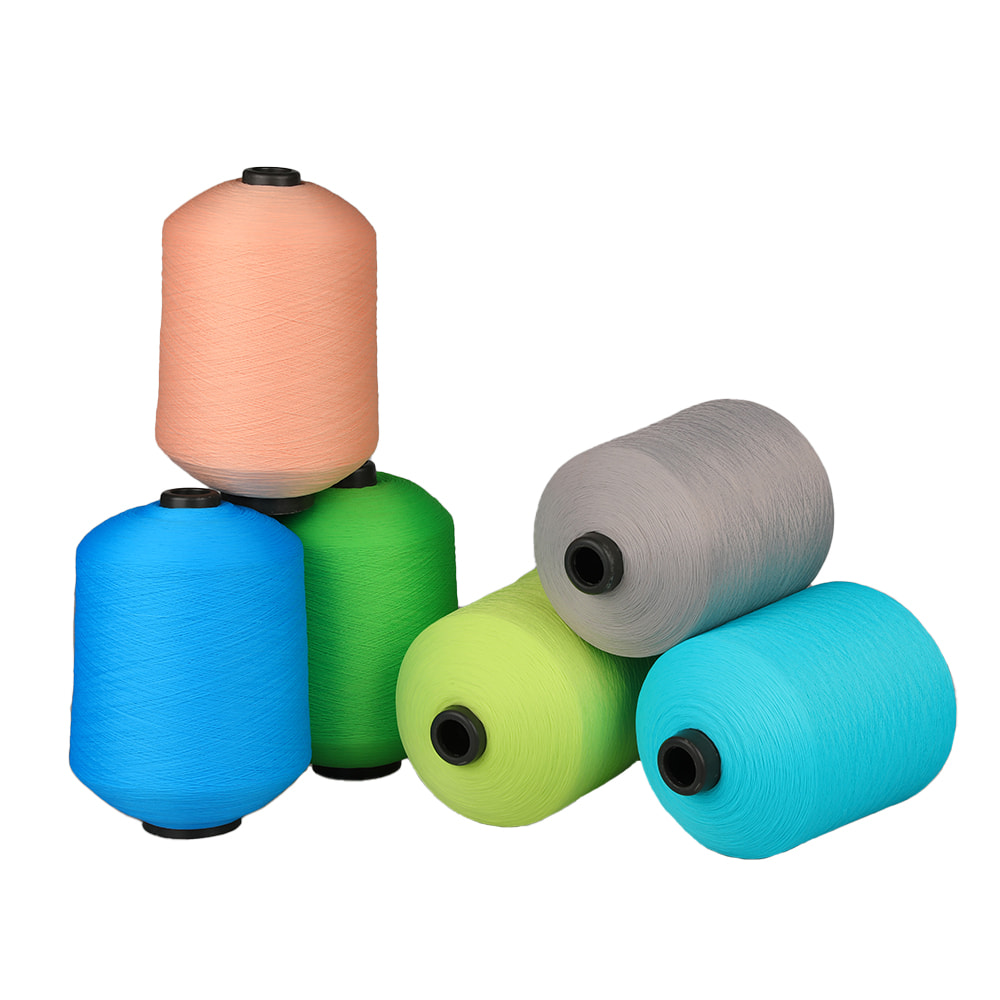

Procuring consistent, high-quality Rubber Band Thread requires a partnership with a manufacturer that possesses deep vertical integration and application expertise. A specialized producer brings control over the entire process, from polymer or latex sourcing to final twisting and dyeing. This ensures batch-to-batch consistency in critical properties like elasticity and thickness—variations in which can cause major production defects in automated garment manufacturing. An ideal partner operates at scale, with a daily output capacity of dozens of tons, guaranteeing reliable supply for large orders. They should offer a vast range, including specialized products like latex free rubber band thread for sensitive markets and clear elastic rubber band thread for aesthetic applications. Furthermore, their expertise should extend beyond production to application support, helping clients select the perfect thread for specific fabrics and end-uses, such as the ideal rubber band thread for garments in sportswear versus intimate apparel. This combination of scale, range, and technical knowledge transforms a supplier from a simple vendor into a value-adding partner in product development.

- Vertical Integration: Control from raw material to finished spool ensures unmatched consistency.

- Scale & Reliability: High-capacity production prevents supply chain disruptions for large projects.

- Comprehensive Portfolio: Ability to supply everything from standard to highly specialized elastic threads.

- Technical Collaboration: Expert support in matching thread specifications to fabric and performance needs.

Working with Rubber Band Thread: Tips for Manufacturers and Crafters

Successful use of Rubber Band Thread, whether in an industrial setting or a home studio, relies on proper technique. When sewing with elastic thread in the bobbin for shirring, always wind the bobbin by hand slowly and without tension to prevent pre-stretching the elastic. Use a longer stitch length and test on a fabric scrap first. For constructing garment casings, the elastic thread is typically not sewn directly but is fed through a tunnel; here, ensure the thread is not stretched while being cut to length to prevent immediate retraction and loss of elasticity in the casing. During industrial manufacturing, proper tension settings on coverstitch and overlock machines are critical to prevent thread breakage or seam puckering. For care, advise end-users to avoid excessive heat in dryers and to wash with mild detergents, as high heat and harsh chemicals can degrade both natural and synthetic elastic fibers over time, leading to loss of recovery.

FAQ

Can rubber band thread be used in a regular sewing machine?

Yes, elastic rubber band thread for sewing can be used in a regular domestic sewing machine, but typically only in the bobbin. It is not recommended for use as the needle thread because its elasticity can cause jamming and inconsistent stitches. When wound onto the bobbin (by hand, under low tension) and used with a standard polyester or cotton thread in the needle, it creates a stretchy stitch on the underside, perfect for shirring or creating elasticated seams on lightweight fabrics. Always test on a scrap first.

How do I prevent elastic thread from breaking during sewing or use?

Breakage usually stems from excessive tension, abrasion, or using a thread with insufficient strength for the application. For sewing, ensure your machine's tension is not too high, especially on the bobbin case if using elastic in the bobbin. Use a fresh needle to prevent snagging. For the final product, specify a high strength rubber band thread that matches the mechanical demands of the garment. For example, a heavy denim waistband requires a much stronger elastic thread than a lightweight blouse cuff. Consulting with your thread supplier on the appropriate denier and core strength is the best prevention.

What is the difference between covered elastic thread and bare elastic thread?

Covered elastic thread has its elastic core (rubber or synthetic) wrapped with inelastic fibers like cotton, polyester, or nylon. This covering protects the core from damage during sewing and wear, provides a surface for dyeing, and makes the thread easier to handle and grip in machinery. Bare elastic thread is just the exposed elastomer filament. It is often clear elastic rubber band thread used for invisible applications but is more susceptible to damage from needles, abrasion, and UV light. Covered threads are standard for sewn-in applications like waistbands, while bare threads are used for hidden stabilization or in specific knitting processes.

How does latex-free elastic thread perform compared to traditional rubber thread?

Modern latex free rubber band thread, typically made from TPU, performs exceptionally well and often surpasses natural rubber in specific areas. It generally offers superior resistance to chlorine, oils, sweat, and UV degradation, making it longer-lasting in swimwear and activewear. It provides consistent elasticity and is hypoallergenic. While some grades may have a slightly different hand-feel than the softest natural rubber, advancements have minimized this difference. For most performance and durability-focused applications, and where allergen concerns exist, high-quality synthetic elastic thread is an excellent, often superior, choice.

What should I consider when specifying rubber band thread for swimwear?

Swimwear presents one of the harshest environments for Rubber Band Thread. The key considerations are: 1) Chlorine & Saltwater Resistance: This is paramount. Specify a synthetic elastomer like TPU, which is inherently resistant, unlike natural rubber which degrades quickly. 2) UV Resistance: For outdoor wear, ensure the thread is stabilized against sunlight. 3) Color Fastness: The thread must not bleed dye into the fabric when exposed to pool chemicals or seawater. 4) High Recovery: It must maintain its elasticity despite constant wet/dry cycles and stretching. Always request and verify test data for chlorine resistance from your supplier when selecting rubber band thread for garments intended for swimwear.

English

English 中文简体

中文简体 Español

Español