At our company, a leading textile engineering and production specialist with decades of experience supplying high‑performing materials to industrial and commercial manufacturers, we understand the strategic value of material selection in textile manufacturing. Fiber Polyester Yarn has become a cornerstone in contemporary textile production due to its unique combination of mechanical properties, processing versatility, and market trends aligning with performance requirements. In this article, we explore the fundamental advantages of this yarn type, its performance characteristics, comparative strengths, and relevant industry insights.

Introduction

Fiber Polyester Yarn is a synthetic filament created through polymerization and spinning of polyester polymers (commonly polyethylene terephthalate). It is widely adopted in textiles for garments, industrial fabrics, home furnishings, and technical applications due to its balance of strength, durability, and cost. According to the latest industry data, polyester fibers accounted for approximately 59% of global fiber production in 2024, reflecting continued adoption in broad sectors of textile manufacturing.

Source: Textile Exchange Materials Market Report 2025

1. Core Benefits of Fiber Polyester Yarn

The primary advantages of fiber polyester yarn properties and textile performance stem from the intrinsic molecular structure of polyester, which confers mechanical reliability and process adaptability. Key performance benefits include:

- High tensile strength ensures resistance to breakage under load.

- Low moisture absorption supports dimensional stability and rapid drying.

- Excellent abrasion resistance extends lifecycle in high‑wear applications.

- Thermal resilience enables tolerance to elevated processing temperatures.

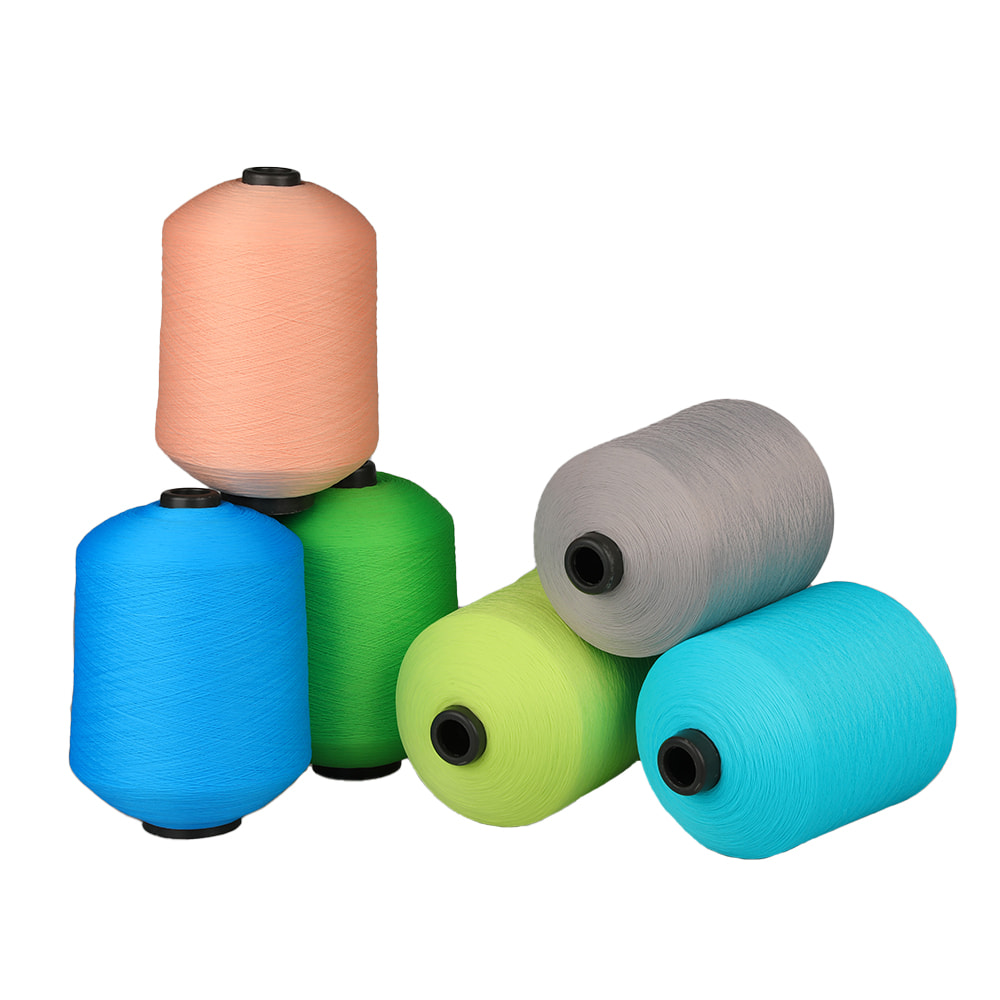

2. Dyeing and Finishing Advantages

One challenge historically associated with polyester fibers is dye uptake. However, advancements in chemistry and process engineering have made best dyeing techniques for fiber polyester yarn fabrics reliable and cost‑effective. Techniques such as disperse dyeing, dope dyeing, and carrier‑assisted methods allow manufacturers to achieve consistent colorfastness, saturation, and recyclability while minimizing energy use and effluent loads.

3. Comparative Analysis with Other Yarn Types

To contextualize the performance of Fiber Polyester Yarn, it is instructive to compare it with natural alternatives such as cotton yarn. In many applications, polyester’s characteristics offer measurable advantages:

In terms of mechanical properties, polyester typically exhibits higher tensile strength and better abrasion resistance compared to cotton, making it more suitable for durable end‑uses such as industrial textiles or performance fabrics.

| Property | Fiber Polyester Yarn | Cotton Yarn |

| Tensile Strength | High | Moderate |

| Moisture Absorption | Low | High |

| Abrasion Resistance | Superior | Lower |

| Dimensional Stability | Excellent | Variable |

This table illustrates why manufacturers often choose polyester for applications where durability, stability, and lifecycle performance outweigh comfort‑centric attributes of natural fibers.

4. Applications and Performance Contexts

Across modern manufacturing, industrial applications of fiber polyester yarn materials include:

- Apparel and activewear that require lightweight strength and quick dry properties.

- Home textiles such as upholstery, drapery, and carpets where abrasion resistance matters.

- Technical textiles like geotextiles, automotive fabrics, and safety belts where engineered performance is required.

Market projections indicate sustained growth in polyester yarn segments due to these versatile applications. For example, the global polyester filament yarn market is expected to expand robustly through 2034, driven by increased utilization in both apparel and industrial sectors.

Source: Business Research Insights – Polyester Filament Yarn Market Growth & Forecast 2025

5. Sustainability and Material Innovation

Ongoing industry focus on sustainability has brought attention to recycled and bio‑based polyester variants. The ability to incorporate post‑consumer PET into yarn production supports circularity without substantial compromises in performance. Manufacturers are increasingly able to meet eco‑efficiency targets by optimizing recycled content and reducing energy footprints during dyeing and finishing.

6. Selection Criteria for Textile Manufacturing

When evaluating Fiber Polyester Yarn for specific use cases, engineers and procurement specialists typically assess:

- Denier and filament count to match mechanical performance requirements.

- Moisture management properties for comfort or industrial environmental demands.

- Dyeability and colorfastness consistent with finishing workflows.

- Recycled content levels aligned with sustainability goals.

Conclusion

In conclusion, Fiber Polyester Yarn remains a highly adaptable and performance‑driven yarn choice in textile manufacturing. Its balanced combination of strength, processing flexibility, and compatibility with advanced dyeing methods makes it suitable for a wide spectrum of applications. As industry standards and market demand continue to evolve, polyester yarn’s role in high‑performance and sustainable textiles is set to expand further.

Frequently Asked Questions (FAQ)

- What makes polyester yarn stronger than cotton? – Polyester’s molecular structure gives it higher tensile strength and abrasion resistance compared to cotton.

- Can polyester yarn be dyed to achieve high colorfastness? – Yes, advanced dyeing methods provide excellent colorfastness and consistent shade delivery.

- Is recycled polyester yarn as durable as virgin polyester? – Modern recycling processes produce yarn with performance properties approaching virgin polyester.

- For which applications is polyester yarn most suitable? – It is ideal for activewear, home textiles, industrial fabrics, and technical applications requiring durability.

- How does polyester yarn contribute to sustainability? – By using recycled PET and optimizing manufacturing processes to reduce environmental impact.

English

English 中文简体

中文简体 Español

Español