How to optimize the spinning and weaving process to improve the quality and performance of composite fishnet yarn?

1. Optimize the spinning process

Raw material selection and pretreatment

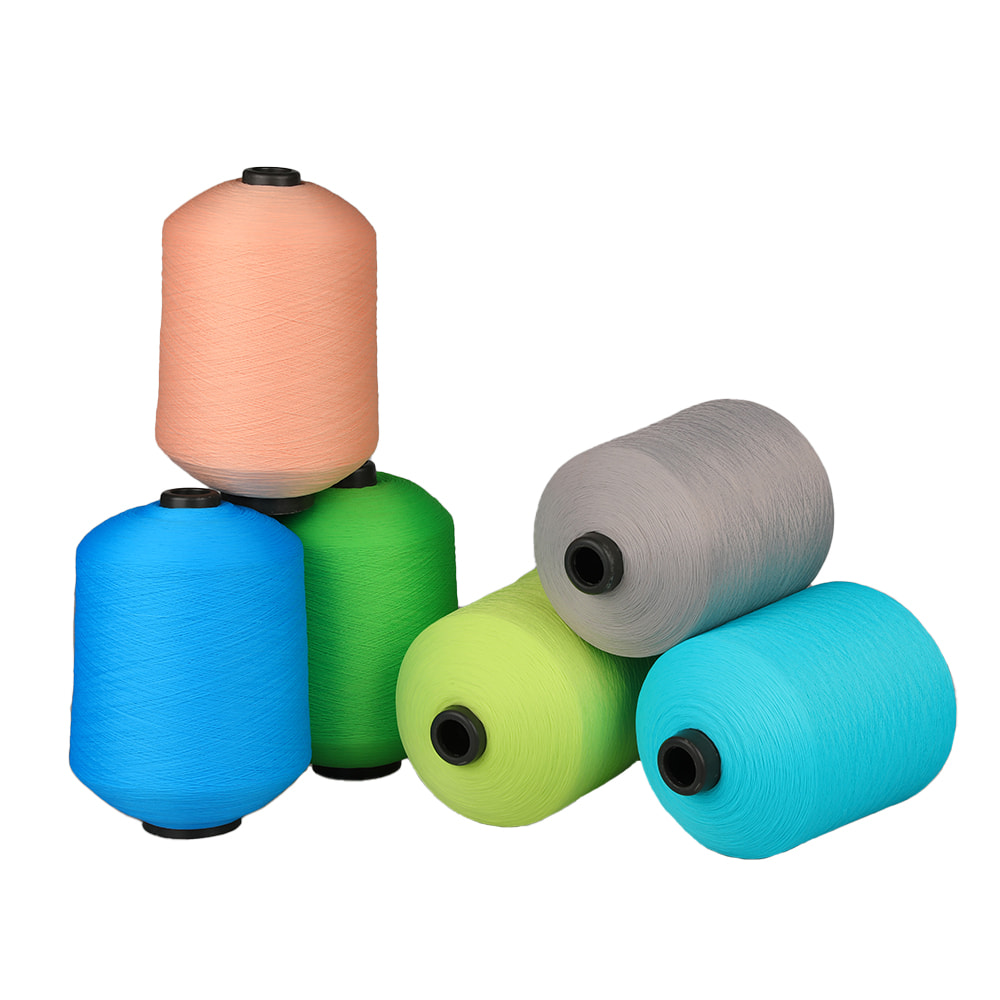

Raw material selection: Select fibers with uniform length, high strength, low curl and uniform color as raw materials. For composite fishnet yarn, it may be necessary to consider the mixing ratio of multiple fibers to achieve the required strength and wear resistance.

Raw material pretreatment: Perform necessary pretreatment on the raw materials, such as cleaning and drying, to remove impurities and moisture to ensure the purity and dryness of the raw materials.

Spinning equipment and technology

Equipment selection: Select appropriate spinning equipment according to fiber characteristics and yarn requirements. For composite fishnet yarn, it may be necessary to adopt multi-component embedded composite spinning technology to achieve uniform mixing and effective spinning of multiple fibers.

Parameter adjustment: Reasonably adjust the parameters of the spinning machine such as tension, rotation speed, and offline tension to ensure the quality and performance of the yarn. Especially for the mixed spinning of different fibers, it is necessary to finely adjust the parameters according to the characteristics of each fiber.

Equipment maintenance: Regularly maintain and service the spinning equipment to ensure the normal operation of the equipment and the stability of the spinning quality.

Spinning process optimization

Process principles: Follow the process principles of "more combing and less falling, light weight, and high tension" to reduce cotton knots and increase the straightness of the fiber.

Drawing and drafting: During the drawing and drafting process, use appropriate drawing numbers and drafting multiples to improve the uniformity and strength of the yarn. For composite fishnet yarns, special attention may need to be paid to the mixing effect of different fibers during drawing and drafting.

Twisting and winding: Reasonably control the twist coefficient and winding tension to ensure the twist and winding quality of the yarn. For composite fishnet yarns that require high wear resistance, the twist coefficient can be appropriately increased to increase the strength and wear resistance of the yarn.

2. Optimize weaving process

Weaving equipment selection

Select weaving equipment suitable for composite fishnet yarn weaving, such as warp knitting machines, weft knitting machines, etc. According to the characteristics of the yarn and weaving requirements, select the appropriate machine number and weaving method.

Weaving parameter adjustment

Reasonably adjust the tension, speed, density and other parameters of the weaving machine to ensure the quality and performance of the woven fabric. Especially for composite fishnet yarn, it is necessary to finely adjust the parameters according to its special structure and purpose.

Weaving process optimization

During the weaving process, adopt appropriate interweaving methods and weaving structures to improve the strength and wear resistance of the woven fabric. For composite fishnet yarn braids that need to withstand greater tension and wear, a tighter weaving structure and higher interweaving density can be used.

Pay attention to quality control during the weaving process, and promptly discover and deal with problems such as broken ends and skipped yarns to ensure the continuity and integrity of the woven fabric.

How can composite fishing net yarn suppliers establish a complete quality control system to ensure the stable and reliable quality of composite fishing net yarn?

1. Clear quality goals

Set clear indicators: Quality goals should be consistent with the overall strategic goals of the enterprise and have clear indicators to measure, such as improving yarn qualification rate, reducing customer complaints, and improving customer satisfaction.

For composite fishing net yarn: Pay special attention to key performance indicators such as yarn strength, abrasion resistance, and aging resistance to ensure that these indicators meet or exceed industry standards and customer requirements.

2. Establish quality control process

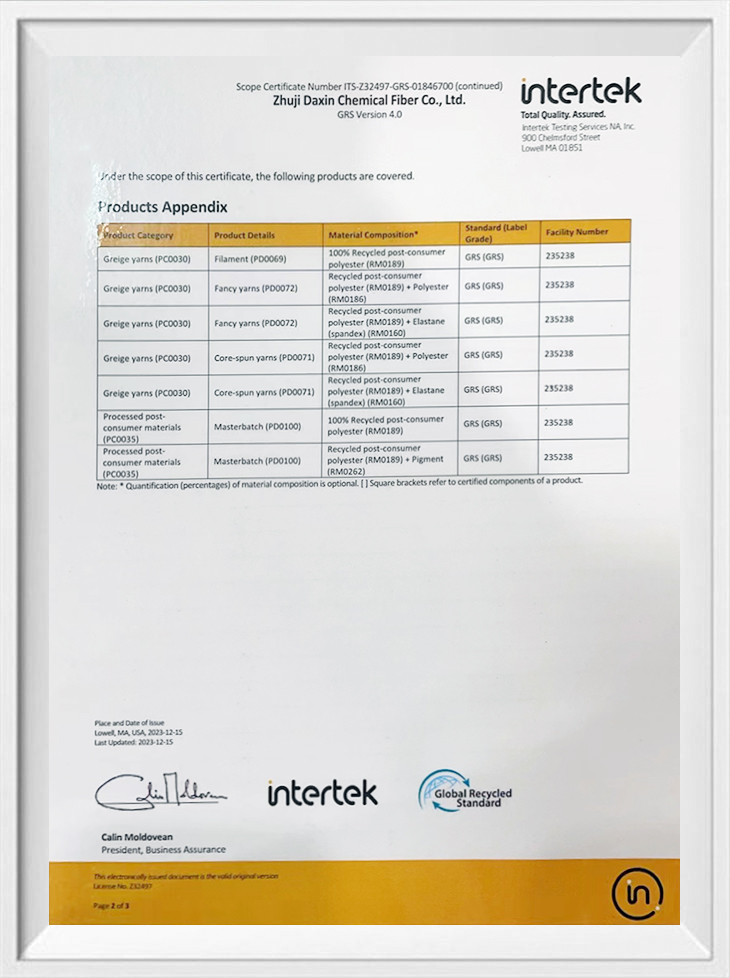

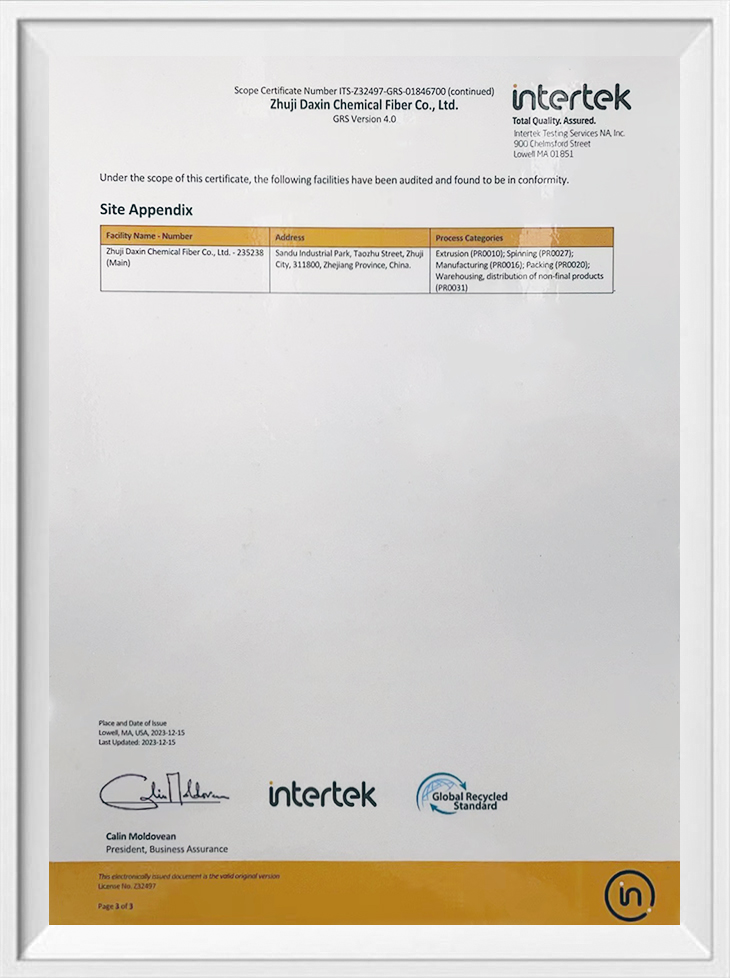

Full process control: From raw material procurement, production process, finished product inspection to shipment, quality control points should be set up in each link.

Raw material procurement: Select fibers with uniform texture, cleanness and compliance as raw materials to ensure stable raw material quality.

Production process: Strictly control the process parameters and equipment status of key links such as spinning, braiding, twisting, impregnation, and drying to ensure the stability and consistency of the production process.

Finished product inspection: Establish a complete inspection mechanism, including incoming material inspection, process inspection, and final product inspection to ensure that the quality of the finished product meets the standards.

Smart cotton matching system: For the various raw material ratios required for composite fishing net yarn, a smart cotton matching system can be introduced to realize method modeling, model dataization, and intelligent cotton matching through databases, model libraries, etc., to improve cotton matching efficiency and accuracy.

3. Formulate quality management standards and specifications

Enterprise standards: Clarify the technical requirements and parameters of composite fishing net yarn, establish enterprise standards, and ensure that all products meet the standards.

Regulatory compliance: When formulating standards, the relevant national and industry regulations and standards should be fully considered to ensure the compliance of the quality management system.

4. Employee training and skill improvement

Regular training: Develop training plans and regularly train employees on quality management knowledge, operating procedures, quality control tools and methods to improve employees' quality awareness and skill levels.

Practical exercises: Through practical exercises and case analysis, employees are familiar with quality control processes and methods and can actively participate in quality control activities.

5. Continuous improvement and innovation

Data collection and analysis: Collect and analyze quality data, identify problems and improvement opportunities, and continuously optimize the quality control system.

Learn from advanced experience: Learn from the successful experience of other companies, introduce advanced quality management methods and tools, such as Six Sigma, PDCA cycle, etc., to improve the level and effect of the quality control system.

Technological innovation: Pay attention to the development trend of industry technology, introduce new technologies, new processes and new equipment, and improve product quality and production efficiency.

English

English 中文简体

中文简体 Español

Español