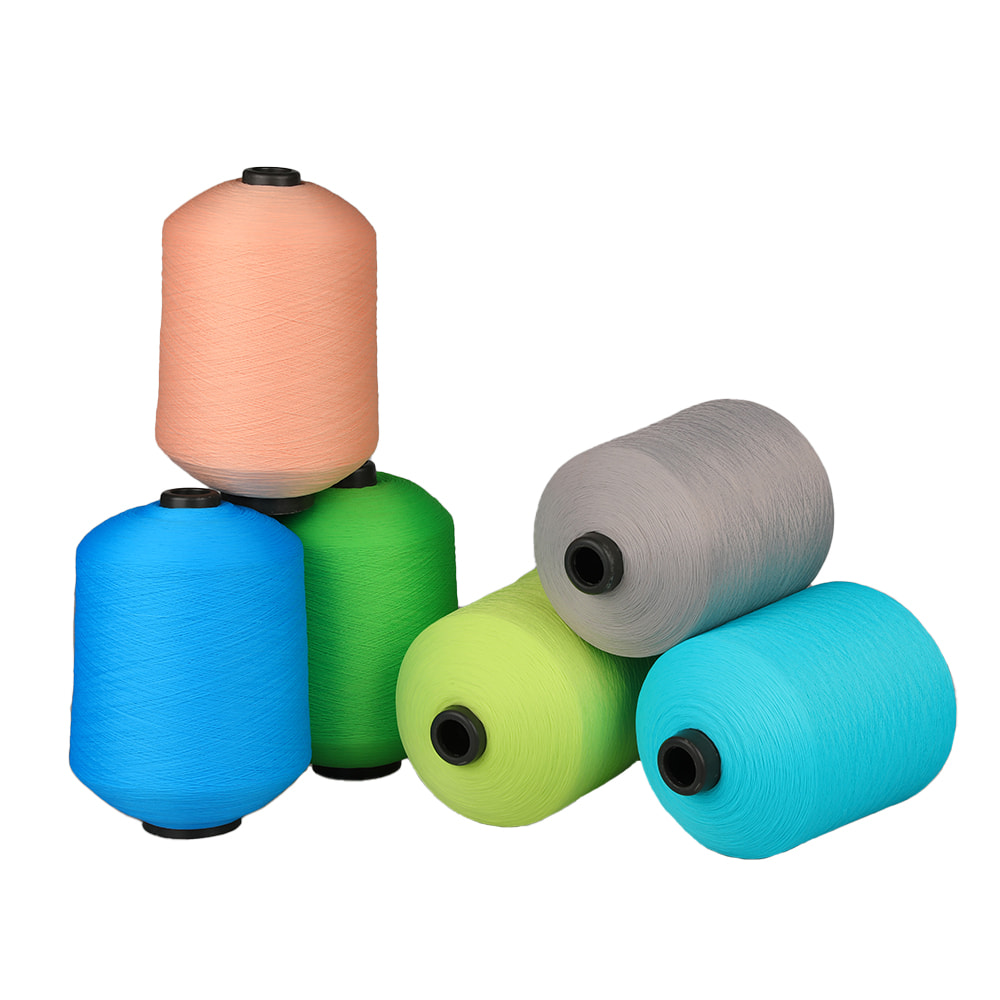

How can manufacturers of recycled environmentally friendly yarns use technical means to reduce the short fibers and cotton knots in regenerated fibers and improve the quality of recycled environmentally friendly yarns?

1. Raw material selection

Preferred raw materials: Select regenerated fibers with good grade, moderate fineness, appropriate maturity, low short fiber rate and impurity rate as raw materials. Such raw materials will produce relatively few short fibers and cotton knots during processing.

Reasonable cotton matching: According to the conditions of production equipment and variety requirements, reasonably match regenerated fibers of different qualities to avoid mixing raw cotton with large differences in short fibers, so as to reduce the difficulty and insufficiency of removing short fibers.

2. Process optimization

Blowing process:

Adopting the principle of short process, early drop, less broken, and more rows, reasonably set the cotton opening and cleaning process to reduce the generation of impurities and short fibers.

Give full play to the role of free opening, hold and strike appropriately, and avoid excessive striking to cause fiber damage.

Adjust the cotton dropping process, organize the airflow distribution, and ensure that each machine absorbs enough air volume to achieve the effect of gradual opening and slow beating, early drop, more rows, and less damage and broken.

Carding process:

Select appropriate metal card clothing, reasonably select matching types, improve the fiber transfer rate, and reduce the generation of short fibers and cotton neps.

Determine the grinding cycle of the card clothing reasonably according to the output and the quality of the raw cotton web.

Adjust the spacing and speed of the cylinder, doffer, cover plate, licker-in roller and other components to optimize the carding effect.

Adopt the process principle of "light weight, small tension drafting, low speed, medium spacing, and small pressure" to reduce the short fiber rate and cotton neps in the raw sliver.

Drawing process:

Adopt two-pass drawing and 8-way drawing to improve the parallel straightness of the fiber and reduce the generation of cotton neps.

Appropriately adjust the roller spacing and tension to avoid the fiber being broken or cotton neps during the drawing process.

Roving process:

Adopt the process principle of "low speed, heavy pressure, and large twist coefficient" to improve the roving level and reduce short fibers and cotton neps.

III. Equipment adjustment

Regularly check and maintain equipment: ensure that the equipment is in good operating condition and reduce fiber damage and cotton neps caused by equipment failure.

Optimize equipment parameters: According to the actual production situation, adjust equipment parameters such as roller speed, gauge, tension, etc. to achieve the best combing and drafting effect.

4. Production management

Standardize production management: formulate a correct production plan to ensure the reasonable arrangement of raw material supply and production progress. Strengthen the management of the production site, strictly implement operating procedures, and avoid production problems caused by human factors.

Strengthen quality inspection: Establish a complete quality inspection system, improve the professional skills of quality inspectors, discover and solve problems in time, and ensure the quality and performance of yarn.

5. Other measures

Control temperature and humidity: During the spinning process, reasonably control the temperature and humidity of the workshop to avoid expansion or contraction of fibers due to improper temperature and humidity, which affects the combing and drafting effects.

Reduce the use of backing: The fibers in the backing have been combed and drafted many times, and it is easy to produce more short fibers and cotton knots when used again. Therefore, the use of backing should be minimized.

How can suppliers of recycled environmentally friendly yarn reduce fiber damage and breakage during the spinning process and improve the overall performance of recycled environmentally friendly yarn?

1. Select high-quality raw materials

Raw material characteristics: Select recycled environmentally friendly fibers with high fiber strength, long fiber length and good wear resistance as raw materials. Such fibers are less likely to break during the spinning process and can maintain good yarn quality.

Fiber pretreatment: Perform necessary pretreatment on the fibers before spinning, such as bleaching and softening, to improve the softness and strength of the fibers and reduce damage during the spinning process.

2. Optimize the spinning process

Adjust process parameters:

Reduce the speed and spindle speed: Appropriately reducing the speed and spindle speed of the spinning machine can reduce the damage to the fibers caused by centrifugal force and static electricity accumulation, thereby reducing the risk of fiber breakage.

Adjust tension: Reasonably control the tension of the yarn to avoid adverse effects of excessive or low tension on the fibers. Regularly check the yarn conveying device and yarn supply system to ensure balanced and stable tension.

Optimize the twisting process: During the twisting process, the twist multiple and the direction of rotation should be controlled to achieve a balance between the softness and strength of the yarn.

Improve equipment configuration:

Choose harder rubber rollers: Harder rubber rollers can increase the yarn dryness and reduce the number of coarse and fine details of the yarn, thereby reducing the risk of fiber breakage.

Optimize the configuration of the licker-in roller: In the cotton combing process, appropriately increase the spacing between the licker-in roller and the cotton feeding plate, reduce the licker-in roller speed, and reasonably configure the tin-thorn ratio and the licker-in roller rack tooth shape to reduce damage to the fiber.

3. Strengthen equipment maintenance and management

Regularly inspect and maintain equipment: Regularly conduct comprehensive inspections and maintenance of spinning equipment to ensure that the equipment is in good operating condition. Timely discover and deal with equipment failures and abnormalities to avoid fiber damage and breakage caused by equipment problems.

Standardize production management: Establish scientific and reasonable production management standards, and clarify various process parameters and quality requirements. Strengthen the management of the production site, strictly implement operating procedures, and avoid production problems caused by human factors.

4. Improve the quality inspection level

Establish a sound quality inspection system: strengthen the quality inspection of yarn production process, timely discover and eliminate defects in yarn. Improve the professional skills and sense of responsibility of quality inspectors to ensure the stability and reliability of yarn quality.

5. Pay attention to customer needs and market changes

Focus on customer needs: pay close attention to changes in market and customer demand for yarn quality, and adjust production strategies and process parameters in time to meet customer needs.

6. Environmental control

Control workshop humidity: Maintaining appropriate humidity in the workshop, such as controlling it at around 67%, can reduce the adverse effects of static electricity on fibers, thereby reducing the risk of fiber breakage.

English

English 中文简体

中文简体 Español

Español