In the process of purchasing raw materials, what specific testing and screening processes do latex rubber band manufacturers have to ensure the elasticity and durability of latex?

1. Demand confirmation and supplier selection

Demand confirmation: Manufacturers first need to clarify their own production needs, including the type, specification, quantity and specific elasticity and durability requirements of latex.

Supplier selection: According to the needs, manufacturers will find and evaluate suitable latex suppliers. In the selection process, factors such as the supplier's reputation, production capacity, quality control system, delivery ability and after-sales service will be considered.

2. Raw material quality inspection

Sample inspection: Manufacturers will require suppliers to provide latex samples and conduct detailed physical and chemical performance tests. These tests may include density, hardness, plasticity, tensile strength, elongation at break, abrasion resistance, aging resistance and other indicators.

Tensile strength and elongation at break: These are key indicators for evaluating the elasticity and durability of latex. The tensile testing machine can measure the maximum bearing force of latex materials when stretched by external forces and the elongation before breaking.

Abrasion resistance: Test the wear of latex materials under repeated friction or contact to evaluate their durability.

Aging resistance: simulate the aging process in the natural environment or under specific conditions of use, test the performance changes of latex materials, and ensure that they can maintain stable elasticity and durability during use.

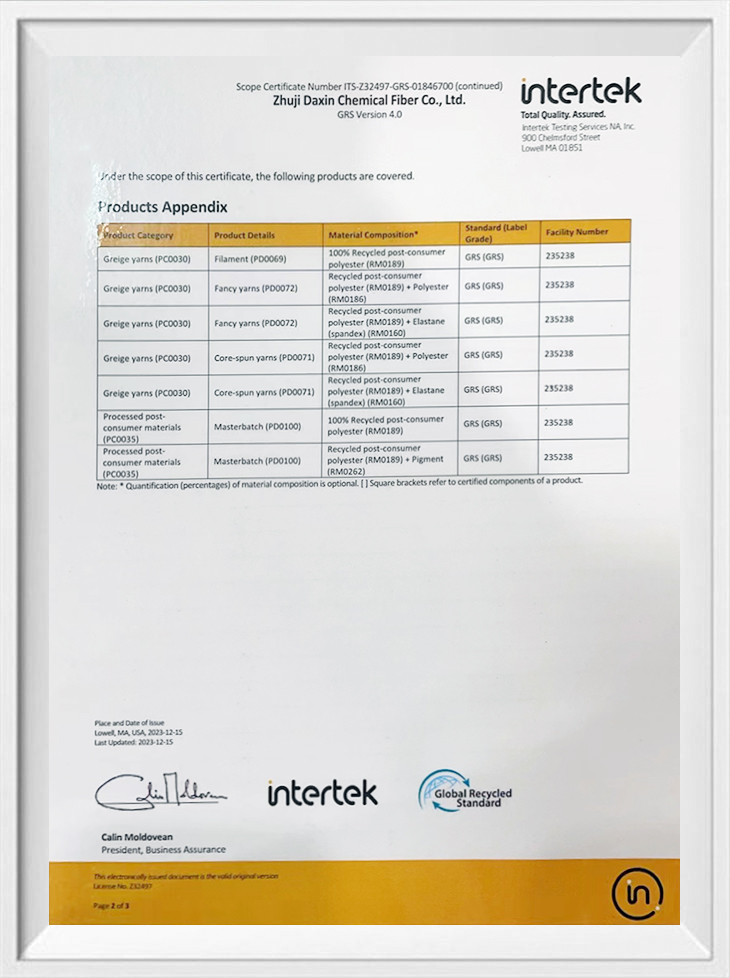

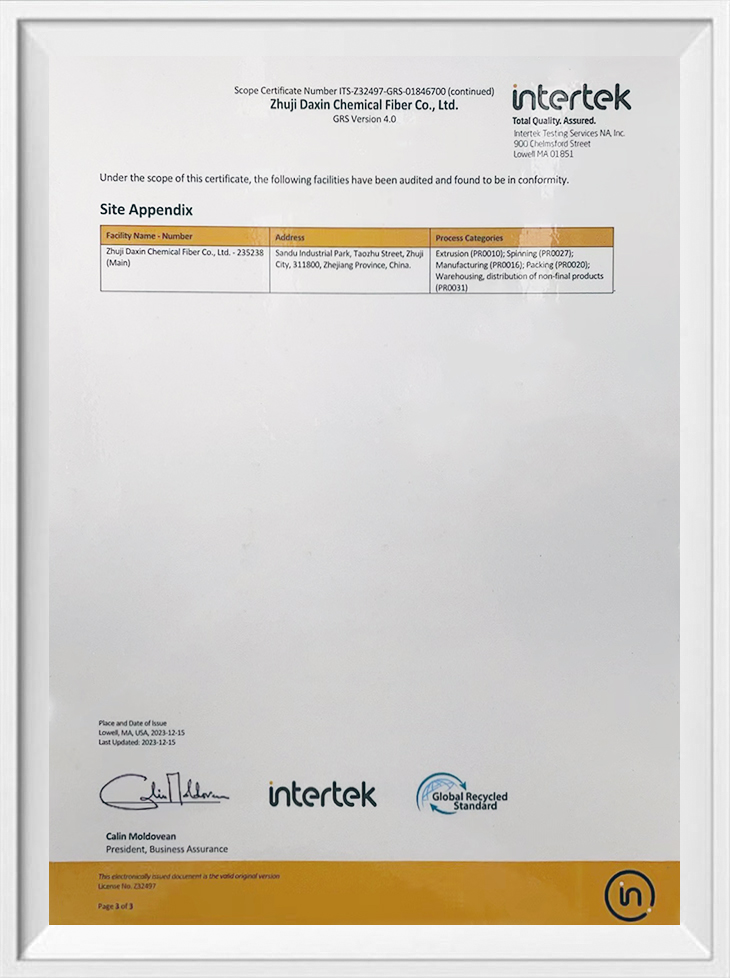

Quality certification: manufacturers will also require suppliers to provide relevant quality certification certificates, such as ISO quality management system certification, environmental protection certification, etc., to ensure that the quality of raw materials meets international or industry standards.

3. Screening and negotiation

Screening: According to the sample test results and quality certification, manufacturers will screen suppliers and select those who can provide latex raw materials that meet the requirements.

Negotiation: negotiate with the selected suppliers on price, delivery date, after-sales service, etc. to reach a cooperation agreement that satisfies both parties.

4. Contract signing and procurement execution

Contract signing: After reaching an agreement in the negotiations, the manufacturer and the supplier formally sign a procurement contract. The contract should clearly state the terms such as the variety, specification, quantity, quality standard, delivery date, and payment method of latex.

Procurement execution: implement the procurement plan in accordance with the contract requirements, and strictly receive and accept the latex raw materials delivered by the supplier.

During the molding process of latex rubber bands, what advanced equipment and technologies do latex rubber band suppliers use to ensure the consistency and accuracy of the products?

Advanced equipment

Mixer: used to mix the latex raw materials to ensure the uniformity of the raw materials, which is the first step in producing high-quality latex rubber bands.

Calender (similar to a rolling machine): press the mixed latex raw materials into thin sheets, similar to the shape of dough, for subsequent processing. This equipment can accurately control the thickness and ensure the uniformity of the product.

Extruder: further process the calendered latex sheets into the shape of a hollow hose. The extruder can accurately control the size and shape of the hose to ensure the consistency of the product.

Vulcanizer: vulcanize the hose at high temperature to make it more elastic and durable. The vulcanizer can accurately control the temperature and time to ensure the stability of the vulcanization process and the quality of the product.

Cutting and packaging equipment: cut the vulcanized latex rubber bands into the required length and package them. These equipment can efficiently and accurately complete the cutting and packaging work, improve production efficiency and product consistency.

Advanced technology

Automation control technology: In the production process of latex rubber bands, the use of automation control technology can accurately control each production link, such as mixing, calendering, extrusion, vulcanization and cutting, etc., to ensure the stability of the production process and the consistency of the product.

Precision measurement technology: Real-time monitoring and measurement of each link in the production process, such as the mixing ratio of raw materials, thickness after calendering, size after extrusion, etc., are carried out through precise measuring equipment to ensure that the product meets the standard requirements.

Quality control system: Establish a complete quality control system, conduct strict inspection and testing of raw materials, production processes and products, and ensure the consistency and accuracy of products. This includes quality inspection of raw materials, sampling inspection during the production process, and comprehensive inspection of finished products.

Environmental protection technology: In the production process of latex rubber bands, environmental protection technology is used to reduce the impact on the environment. For example, environmentally friendly vulcanizers and additives are used to reduce the emission of waste gas, wastewater and waste residues.

English

English 中文简体

中文简体 Español

Español